The advantages of MY-CAP 3000 ECO

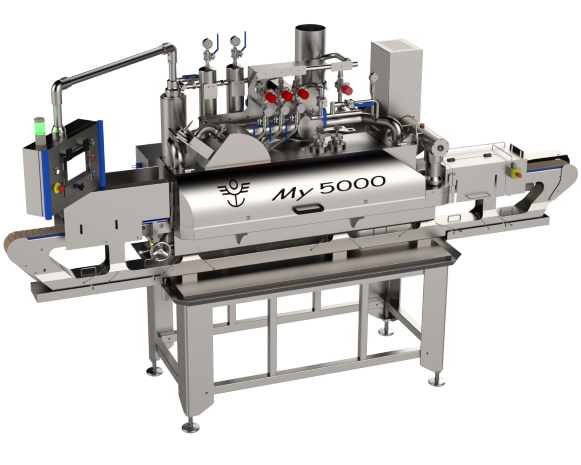

- Fully automated capping machine using brushless and I/O link technologies

- The innovative steam flow system allows low steam consumption

- The differential speed of the gears allows for optimal tightening

- The 9” touch screen allows for intuitive handling, maintenance assistance and easy management of the 40 available recipes

- The ergonomics and accessibility of the machine allow a format change in less than 3 minutes

- The change of wearing parts is done in less than 4 minutes

- The supervision allows for feedback of production information accessible on HMI or on your system

- Remote maintenance is provided via secure modem