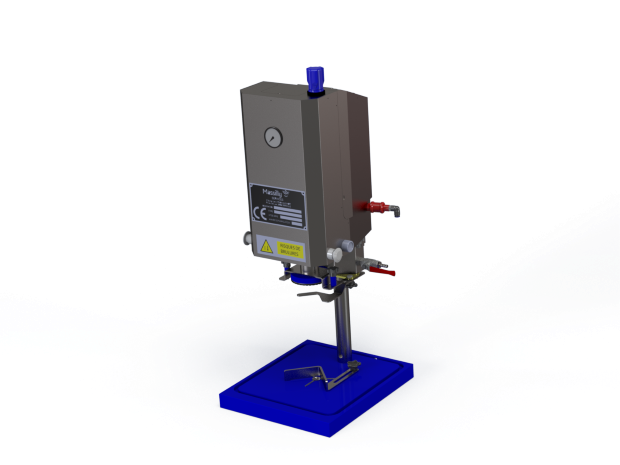

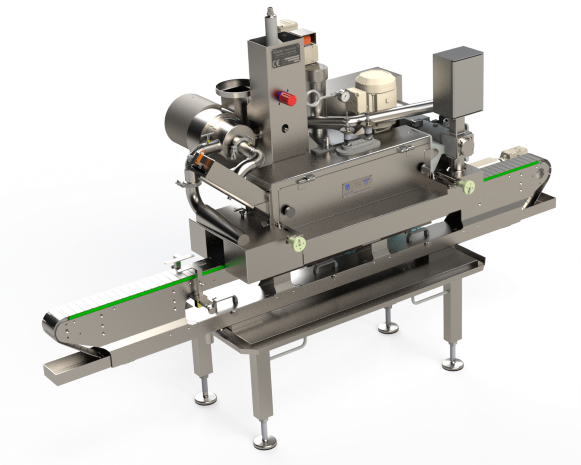

Manual capper

THE “ADVANTAGES” OF MY-CAP MICRO

- Model for R&D department and small productions

- Format change < 5 min, effortless thanks to the integrated pneumatic assistance

- Unscrewing/screwing cycle allowing more efficient capping

- Operates only with compressed air

- Combined with a capping table and a mini generator, this forms a compact and easy-to-use unit