Spreads, whether cheese, vegetable or fish based, represent a category of delicious and versatile products that have conquered the taste buds of consumers around the world.

As a supplier of specialized machines such as dosers, cappers, crimpers, closers, as well as head and end of line equipment, we are constantly adapting to make your needs, your products and our machines compatible.

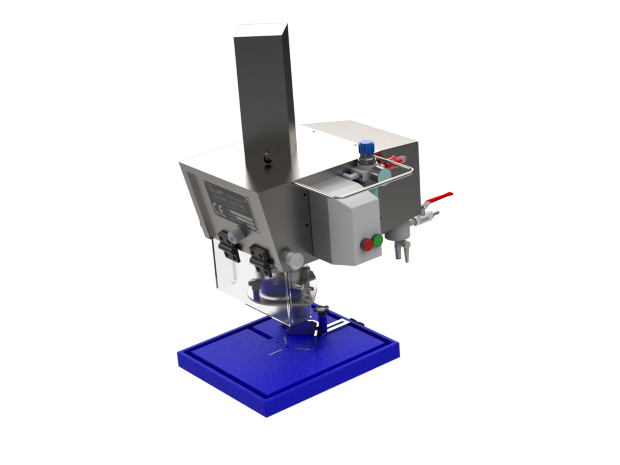

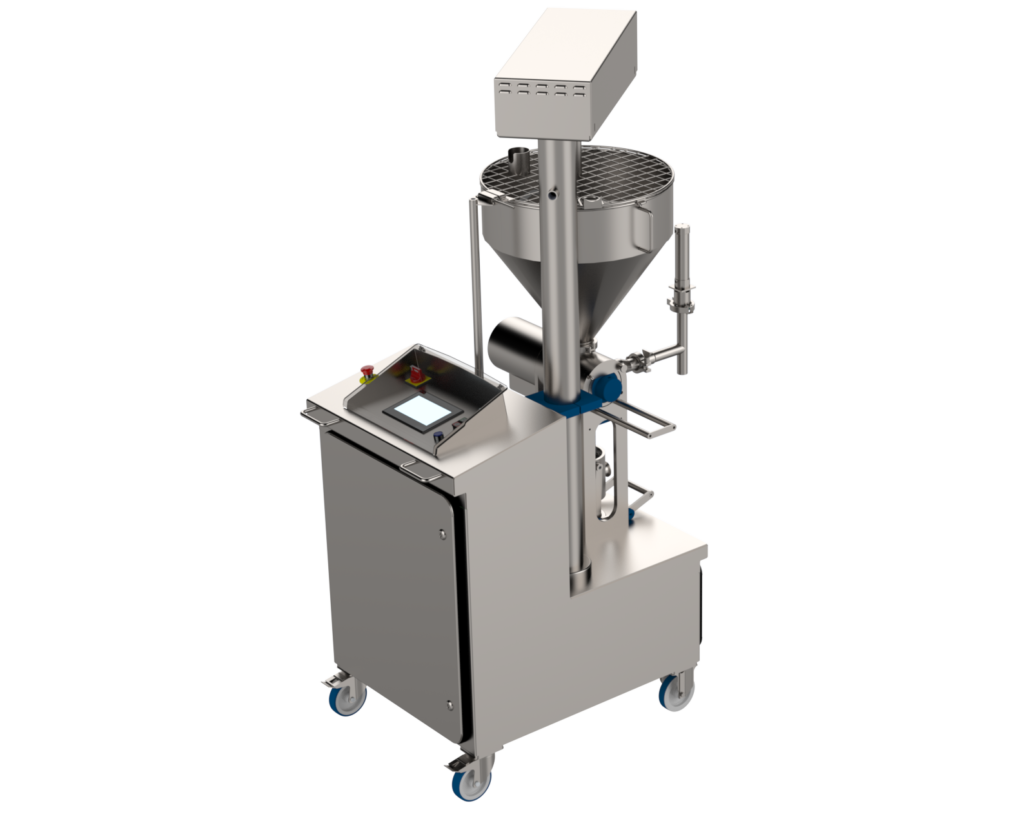

The lobe or piston dosing machine, single or multi-head, semi-automatic or automatic, ensures precise filling, allowing optimal potting for each portion and guaranteeing uniformity of texture and flavor.

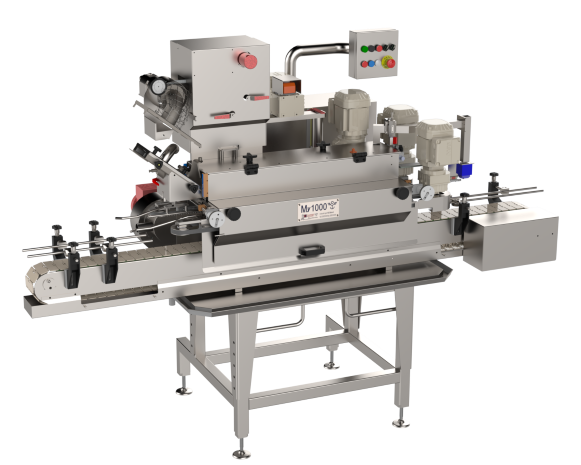

The semi-automatic (from 600 to 1200 jars/hour) and automatic (from 1800 to 30,000 jars/hour) capper for Twist Off (Eurotwist), PT, CT capsules plays a vital role in ensuring hermetic sealing, preserving the freshness of the spreads while extending their shelf life. Thanks to our cutting-edge technology, the capper is capable of closing a wide variety of formats and types of containers (glass and jars), ensuring adaptation to the diverse requirements of the spreads industry.

The seamer for seaming your round cans with diameters from 52.5mm to 153mm. Automatically with a maximum speed (depending on format and product) of up to 60 cans per minute.

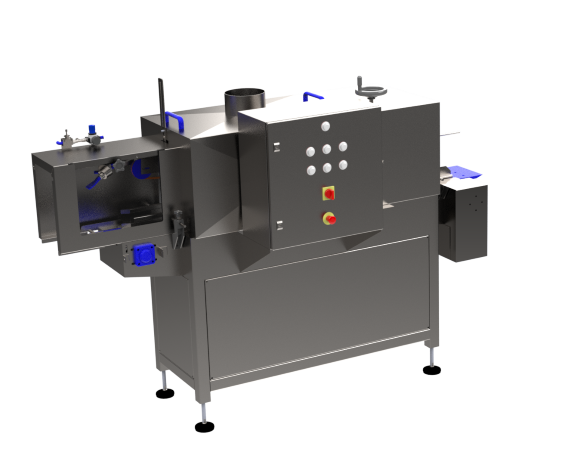

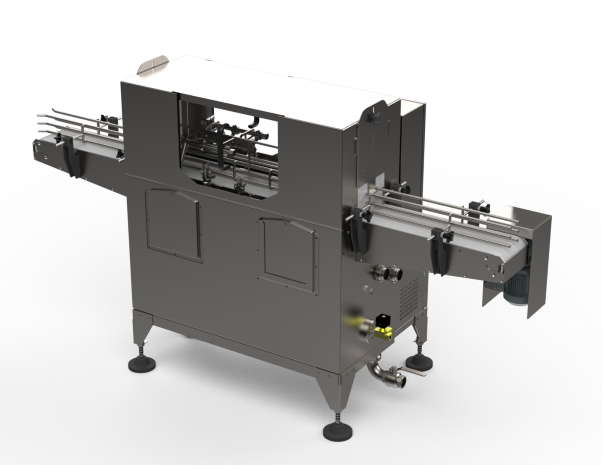

The manual or automatic multi-lane closer will allow you to create a vacuum (avoiding placing the staples on the Weck jars) in your WECK and LE PARFAIT brand glass jars before placing them in an autoclave basket via our caging tables.

These machines are designed to handle the variety of packaging formats, pot sizes and product densities specific to spreadables, ensuring a smooth transition between the different stages of the production line.

Machines suitable for spreads:

Filling machines

Filling machines

Head and end of line

Head and end of line

Other machines suitable for spreads

Forms

Contact us so that we can study together the most effective way to meet your needs.